Unlocking Warehouse Efficiency with Pallet Racking Load Capacity Chart: Safety and Optimization Combined

Unveiling Inefficiencies and Hazards

Overlooking pallet racking load capacity can lead to workplace accidents, diminished productivity, and costly equipment repairs. Understanding the optimal weight distribution on your warehouse racking systems is crucial for ensuring a safe and productive work environment.

Empowering Safe and Efficient Warehousing

A load capacity chart serves as a guiding tool for warehouse managers to determine the maximum weight each rack can safely support. It helps prevent overloading, which can cause structural failure, collapse, or personal injury. By following these guidelines, you can optimize warehouse operations, minimize risks, and protect your valuable assets.

Understanding the Load Capacity Chart

These charts typically include specifications for different rack types, beam lengths, and upright heights. They provide clear indications of the maximum weight capacity for each rack configuration, allowing for precise placement of heavy materials. Adhering to the load capacity limits ensures the safe operation of forklifts and other equipment while preventing rack damage.

The Evolution of Safety Standards

The pallet racking load capacity chart has undergone significant advancements over the years, driven by industry regulations and technological improvements. Modern charts incorporate high-strength steel materials, innovative design techniques, and rigorous testing procedures to ensure maximum stability and longevity.

Unveiling Hidden Hazards

Beyond the obvious risks, overloading can lead to hidden structural damage that may compromise the overall integrity of the racking system. This can result in catastrophic failures, escalating repair costs, and potential legal liabilities.

Recommendations for Optimal Use

To ensure optimal performance and safety, it’s imperative to:

• Consult the load capacity chart before loading racks.

• Distribute weight evenly across all beams and levels.

• Avoid overloading any single beam or section.

• Inspect racks regularly for any signs of damage.

Factors Influencing Load Capacity

The load capacity of pallet racks is influenced by several factors, including:

• Rack design and construction

• Height and span of the rack

• Load type (e.g., static or dynamic)

• Environmental conditions (e.g., temperature and humidity)

Tips for Safe and Efficient Warehousing

• Train warehouse personnel on load capacity limits.

• Implement a regular inspection and maintenance program.

• Use high-quality pallets that are in good condition.

• Avoid using damaged or bent racks.

Optimizing Warehouse Layout

The load capacity chart is essential for planning an efficient warehouse layout. By considering the weight and dimensions of stored items, you can determine the appropriate rack spacing, aisle widths, and equipment requirements to maximize space utilization and facilitate smooth material flow.

Fun Facts about Pallet Racking

• The first pallet racking system was invented in 1930 by Clark Equipment Company.

• The tallest pallet rack ever built was 137 feet tall, constructed by SSI Schaefer in 2010.

• The largest pallet rack facility in the world is located in the Netherlands and has a capacity of over 1 million pallets.

![]()

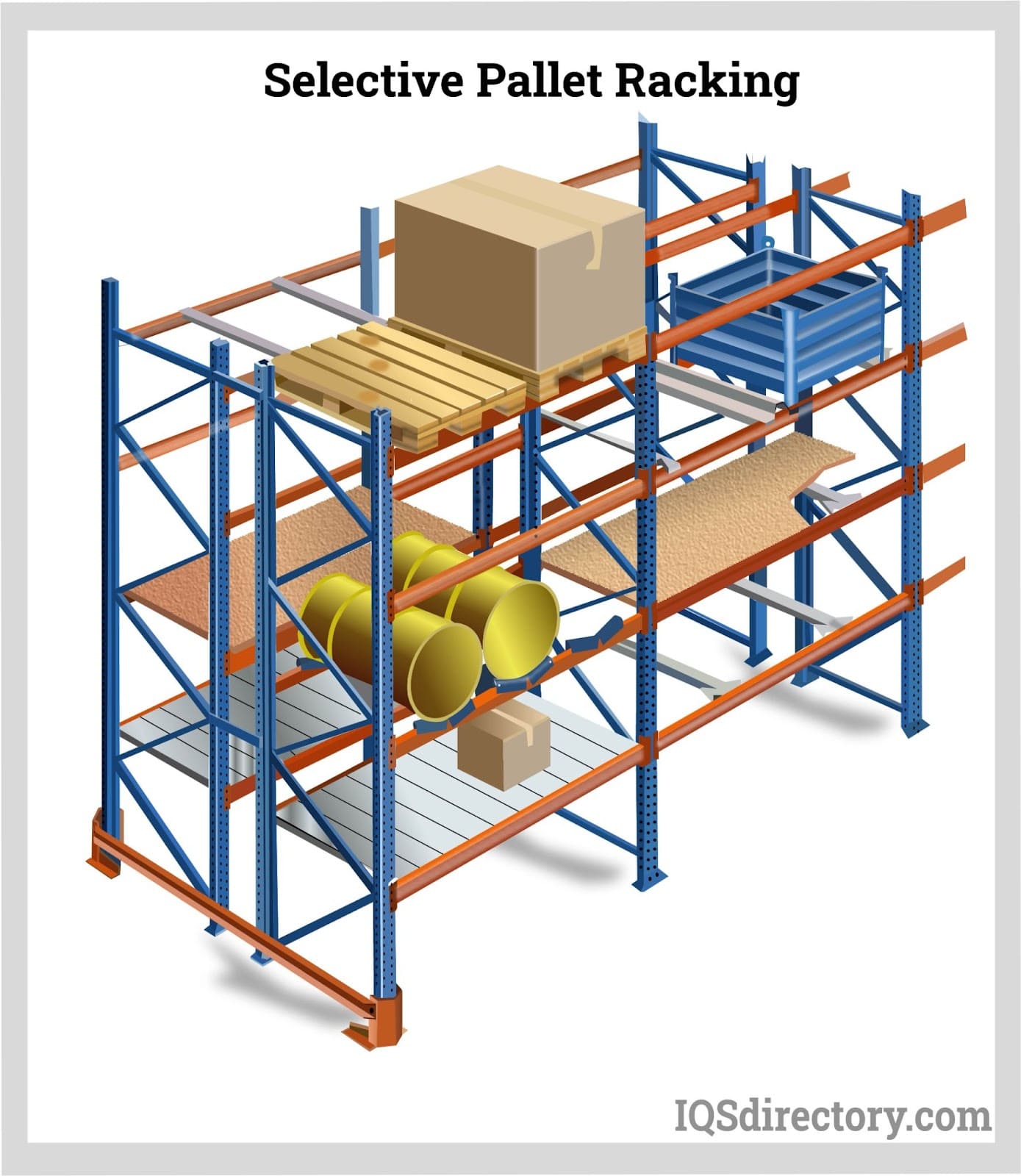

How to Choose the Right Pallet Racking System

Choosing the ideal pallet racking system involves several steps:

• Determine the weight and dimensions of your stored items.

• Consider the available warehouse space and height.

• Select the appropriate rack type (e.g., selective, double-deep, drive-in).

• Choose high-quality racks from reputable manufacturers.

What if You Overload a Pallet Rack?

Overloading a pallet rack can have catastrophic consequences, including:

• Rack collapse, resulting in damage to stored items, equipment, and personnel.

• Structural damage, compromising the integrity of the entire racking system.

• Reduced efficiency due to downtime and repairs.

A Listicle of Pallet Racking Load Capacity Chart Benefits

• Improved safety for warehouse personnel.

• Reduced risk of rack failure and equipment damage.

• Optimized warehouse layout and space utilization.

• Enhanced productivity and efficiency in material handling.

• Compliance with industry regulations and standards.

Questions and Answers

• What is the purpose of a pallet racking load capacity chart?

• How often should I inspect my pallet racks?

• What are the signs of overloaded racks?

• What happens if I overload a pallet rack?

Conclusion

By utilizing the pallet racking load capacity chart and adhering to recommended load limits, warehouse managers can create a safe and efficient work environment while optimizing storage capacity and minimizing operational risks. By empowering warehouse personnel with the necessary knowledge and tools, you can safeguard your assets, enhance productivity, and ensure the longevity of your racking systems.